Basic Info.

Model NO.

QT347N

Driving Mode

Worm Gear

Nominal Pressure

150lb-2500lb

Channel

Full Bore

Structure

Top Entry Trunnion Ball Valve

Type

Metal Seated Top Entry Ball Valve

Function

Blow-Down Valve

Temperature

High Temperature

Standard

API 6D, API 608,ASME B16.34, Mss Sp-72; BS5351

Application

Industrial Usage

Design & Manufacture

API 6D, ASME B16.34

Pre-Temp. Rating

ASME B16.34

Face to Face

ASME B16.10

Ends Connection

RF, Rtj, Bw, NPT, Sw

Special

Nace Mr-0175

Test Certificate

En1024 3.1; Certificate Provide Rt, Mt, PT, Ut

Certificate

ISO 9001, CE,API 607,API 6D

Quality Guarantee Period

18 Months

Supplier

Factory Direct

Type of Shipping

by Sea, by Air

Transport Package

Plywood Wooden Case

Specification

100X100X100(CM)

Trademark

SHF/OEM

Origin

Jiangsu

HS Code

8481804090

Production Capacity

5000000

Packaging & Delivery

Package Size

100.00cm * 100.00cm * 100.00cm

Package Gross Weight

500.000kg

Product Description

Construction is as follows

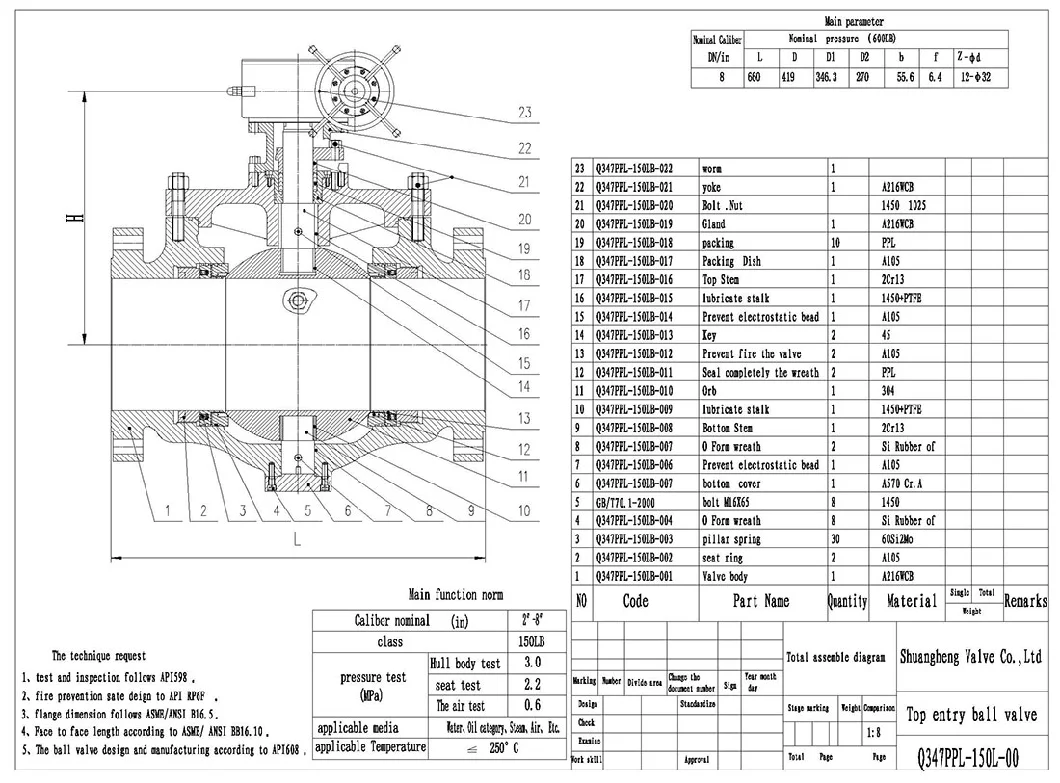

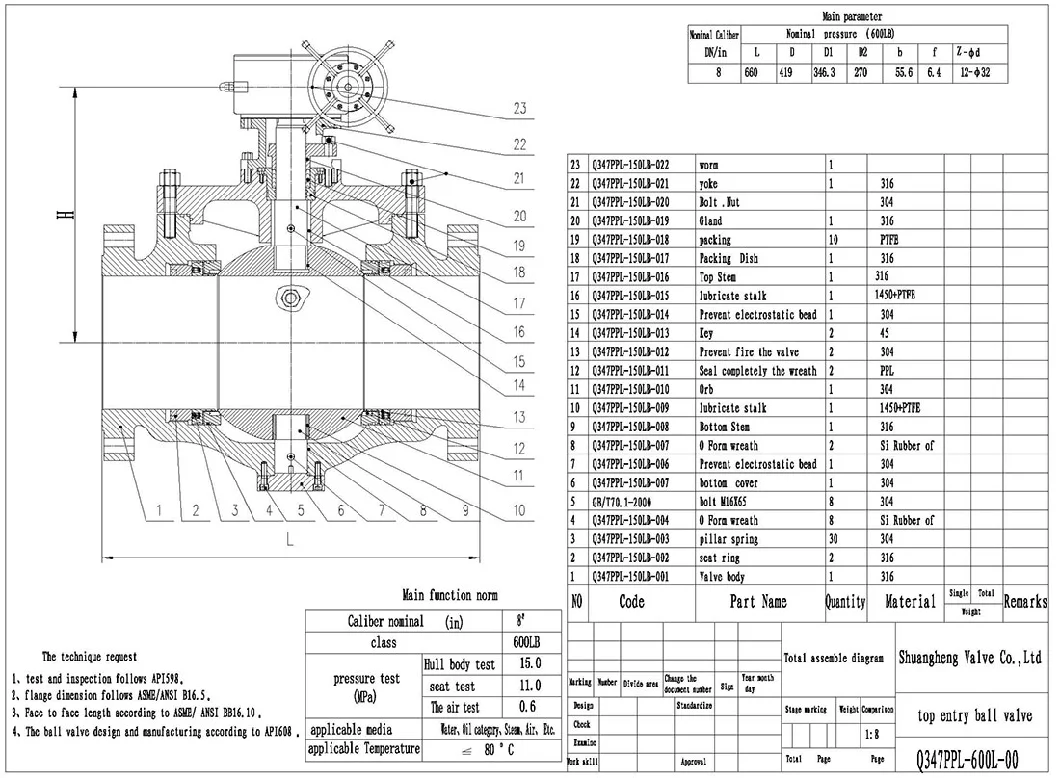

| Name | Top Entry Ball Valve |

| Size | DN15-DN600 |

| Normal pressure | Class 150/300/600/900/1500/2500; PN16/PN40/PN64/PN100/PN160/PN250 |

| Design standard | API 6D, API 608,ASME B16.34, MSS SP-72,BS5351; ISO17292,EN13709 |

| Marked | MSS SP-25 |

| Fire safe design | API607,API 6FA |

| End flange | ANSI B 16.5,ASME B16.47; EN1092,DIN2543~DIN2547,AS2129 |

| Face to Face | ANSI B 16.10,API 6D; DIN3202,EN558-1,EN12982,ISO 5752 |

| Top flange | ISO 5211 |

| Test standard | API598,API6D; DIN3230, EN12266,ISO 5208 |

| Suitable temperature | -10~200°C |

| Medium | Fresh water, sewage, sea water, air, vapor, food, medicine, oils, alkalis, salt etc. |

| Acidic environment | NACE MR0175 |

| Operation | Hand Operated,Gear Operated, Electrical Actuated, Pheumatic Actuated |

Structure

| - Full Port or Reduce Port |

| - One Piece Body,Top Entry,Floating or Trunnion Mounted |

| - Bolted Bonnet with spiral-would gasket |

| - Fire Safe Design |

| - Anti-static Design & Blow-out proof stem |

| - Double seat structure |

| - Nace MR-01-75, Optional Locking Device |

| - The action principle is when the handle drives the stem & ball with 90°rotation to open & close valves. When handle is parallel with body channel, valve is opening. On the contrary, when the handle is perpendicular to body channel, valve is closed. The locating plate can do the limit control. |

| - The seat is double sealing and soft sealing. These're very convenient to replace, and the technology is also very simple. |

| - Direct mounting pad also called Top mountain Flange, is suitable to this ISO 5211 Standard. |

1:The top enty ball valve features with integral body, top trunnion mounted ball. This type of valves gives convenient of in-line repair or repalcing valve internal components without removing the body from the pipeline. The seat seal design uses unique two-level soft sealing and metal to metal sealing to from triple sealing. The seat piston is designed after accurate calculation to ensure sealing reliablility with small open/cloae torque and easy operation. The valve is widely used in the nature gas and oil pipeline, thr industries of petrochemical, medicine, city construction, etc.

2:Its most difference from common ball valve is that its maintenance can be made on pipe line and without dismounting from the pipe line. The back space seat structure is adopted for the seat and the rear portion of seat retainer is oblique angle to prevent accumulation of impurity from affecting back space of seat.

3:It's featured by its small torque and reliable seal; and unlike common ball valve types, its seat with a spheroidal structure can adjust the seal position automatically.

4:Trunnion-mounted ball: Features a fixed ball and floating seat rings. Bearings absorb the side load generated by the pressure acting on the ball.

5:Independent ball and stem: The ball and stem are independent to minimize the effect of side thrust from pressure acting on the ball.

6:Double block and bleed (DBB): Both seats hold their respective pressures independent of the body cavity pressure which is ideal

to verify the sealing of the seats.

7:Self-relieving seat rings- two seat rings assure bi-directional sealing of the valves.

8:Soft-seated valves: In valves designed for standard service, a resilient material is inserted into the metal seat holder to provide a soft-seating acting in addition to the metal-to-metal seating between the ball and seat rings.

Optional Features

1:Emergency sealant injection stem seal and seat face

2:Metal seated valves

3:Double piston effect seats

4:Extended stem and fittings for below ground service

5:Numerous body, trim, seal area overlay and seal materials available

Main Part & Materials

| Part Names | Part Materials | ||||||

| Body | WCB/A105 | LCB/LF2 | CD4MCuN/F51 | CF8/F304 | CF8M/F316 | CF3/F304L | CF3M/F316L |

| Bonnet | WCB/A105 | LCB/LF2 | CD4MCuN/F51 | CF8/F304 | CF8M/F316 | CF3/F304L | CF3M/F316L |

| Ball | A105+ENP | SS304 | F51 | SS304 | SS316 | SS304L | SS316L |

| Stem | A105 | F304 | F51 | F304 | F316 | F304L | F316L |

| Trunnion | A105 | F304 | F51 | F304 | F316 | F304L | F316L |

| Bearing | 304+PTFE | 304+PTFE | 316+PTFE | 304+PTFE | 316+PTFE | 304L+PTFE | 316L+PTFE |

| Antistatic spring | A313-304 | A313-304 | A313-316 | A313-304 | A313-316 | A313-316 | A313-316 |

| Seat Retainer | 13%Cr | SS304 | F51 | SS304 | SS316 | SS304L | SS316L |

| Seat Spring | A313-304,A313-316,Inconel X-750 | ||||||

| Seat Seal Ring | RPTFE/ PTFE/ PEEK/ NYLON/ DELRIN | ||||||

| Packing | Graphite/PTFE | ||||||

| Gasket | SS304+Graphite/SS304+Graphite | ||||||

| Bolts/Nuts | B7/2H | L7/4 | B8M/8M | B8/8 | B8M/8M | B8/8 | B8M/8M |

| Suitable Medium | W.O.G etc. | HNO3, CH3OOH etc. | |||||

| Suitable Temperature | -29~150 °C | -46~150°C | -29~150 °C | --29~150 °C | -29~150 °C | --29~150 °C | -29~150 °C |

Product Size

Product Display

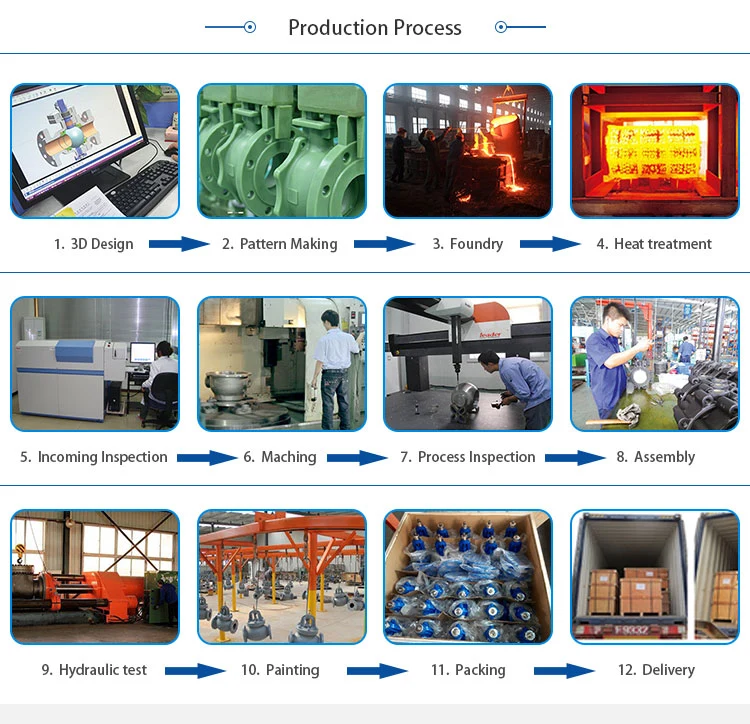

Company Introduction

FAQ

FAQ Q:Why choose us ?

A: we are a manufacturer, we have manufactured valve for over 20 years .

B. We have our own casting foundary in a large scale

Q. what is your payment term?

A: T/T , L/C or other acceptable payment.

Q :Can we print our logo on your products?

A: yes, we offer OEM/ODM service, we support the customized logo, size, package,etc.

Q: what is your main market?

A: North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe

Q: Can I get samples from your factory?

A: Yes, Samples can be provided.

Q: If products have some quality problem, how would you deal with?

A: We will responsible for all the quality problems.

Q:How about your capacity?

A:We have 300staffs,own 50 CNC machines,and five persons in charge of quality inspection and 5 engineers. Our 6 casting block workshops

can both ensure on time delivery and quality that last.