Basic Info.

Model NO.

Z45X

Actuator

Manual

Seal Surface

Wedge Gate Valve

Thread Position of Valve Rod

Inside Gate Valve

Usage

Regulation, Safety, Emptying, Drain, Temperature Control, Flow Control

Standard

Dinf4 BS5163

Application

Industrial Usage, Water Industrial Usage, Household Usage

Water-Using Valve

Gate Valve

Body Material

Ductile Iron/Wcb/Cast Iron

Connection

Flange Ends

Color

Ral5005/5015/5017 or Customer Required

Medium

Normal Temperature Liquid

Size

DN50-DN1200

OEM ODM

Yes

Original

Tianjin, China

Transport Package

in Polywood Case

Specification

DN50 -DN1200

Trademark

BOHAI

Origin

China

HS Code

8481804090

Production Capacity

50000 PCS Per Year

Product Description

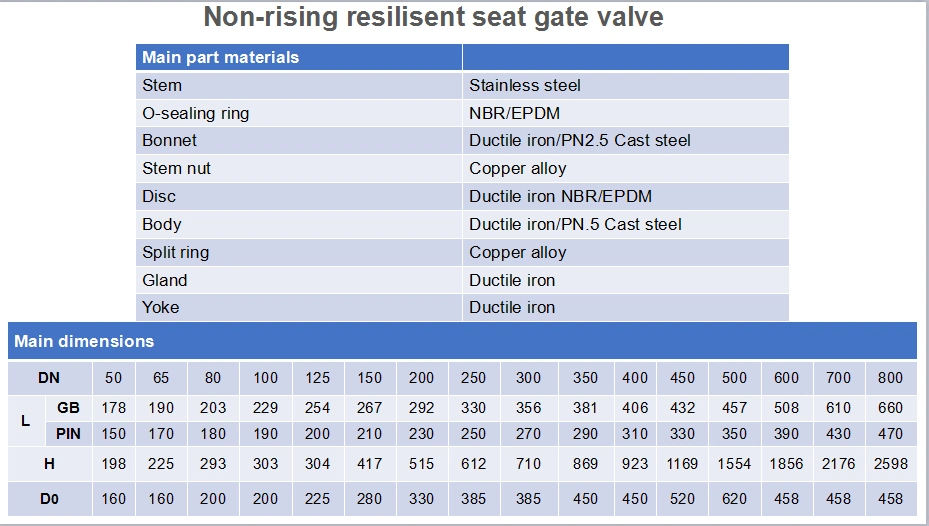

DIN F4 Double Flanged Resilient Seat Sluice Water Gate Valve

Resilient Seated Gate Valves are designed to last long years of operation in many conditions.

With its bolted bonnet structure, EPDM covered wedge and hygienic coating, ready to meet the demand for potable water & sewage applications.

| Design and manufacture standard | CJ/T216-2005 |

| Structural length | GB/T 12221 |

| Size of flange | GB/T 17241.6(cast iron),GB/T9113.1(cast steel) |

| Test and inspection | GB/T 13927 |

1.GGG40/50 Ductile Iron Body & Disc allows high impact and streching resistance

2.With Full Bore design, ensures minimized pressure loss and increased energy efficiency

3.Maintenance free valve design

4.Fully EPDM vulcanised wedge maintains full stop of flow and can absorb smaller particules in the flow. (NBR coated wedge is optional)

5.Stainless steel stem with threads for high strength

6.Maintenance-free and corrosion-resistant multi stem O-rings ensures higher durability

7.Brass wedge nut provides fixation of the stem and low torques.

8.With isolated bonnet nuts, no risk of corrosion

9.Bidirectional use. Possible to install on horizontal and vertical pipelines with varied flow directions

10.Fixed wedge structures prevents vibrationWith precise machined stem, ensures low torque requirements during operation

11.Full coating on the body and disc internally & externally with an average of 250 microns. Higher coating thicknesses are available when required.

12.WRAS approved coating available upon request which meets hygienic requirements for potable water applications

13.For big size valves, balanced positioned lifting holes on the body ease transportation and installation

14.Suitable for vacuum conditionsSuitable for shut-off and isolation purposes.

15.Not suitable for regulation purposesElectrical actuator connection is done with an intermediate top flange arrangement

16.Suitable to use with above-underground applications.

17.Can be operated with handwheel, gearbox, actuator and spindle.

18.Hydrostatic test pressure for seat: PN x 1.1 , for shell: PN x 1.5 according to EN 12266-1.

Q: Are you trading company or manufacturer ?

A: We are factory Located In Tianjin, China.

Q: What's your product range?

A: We produce Butterfly valve, Gate valve, Check valve, Y strainer ,Water Controlling Valve and other Pipe Accessories .

Q: What's Execution Standard?

A: ISO/ANSI/DIN/JIS/ EN/GOST/AS standard.

Q: What's your Strong product ?

A: Centre Line Butterfly valve, Eccentric Butterfly valve ,Resilient Seat Gate valve, and largest size to DN3200 .

Q: How long is your delivery time?

A: Generally it is 10 days if the goods are in stock. or it is 35 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=10000USD, 100% in advance. Payment>=10000USD, 30% T/T in advance ,balance before shipment.